Project Overview

This inventory optimization analytics project leveraged advanced data science techniques to significantly improve

demand forecasting accuracy and inventory management for a major retail organization. By implementing machine learning

models and statistical methods, we achieved more precise demand forecasts and optimized inventory levels across all

product categories and distribution centers.

Business Challenge

Inventory management is a critical challenge for retail organizations, balancing the need to minimize costs while

ensuring product availability. Traditional forecasting methods often struggle with seasonal variations, promotions,

and market fluctuations, leading to excess inventory or stockouts. The client needed a sophisticated solution to

address these challenges at scale.

Technical Solution

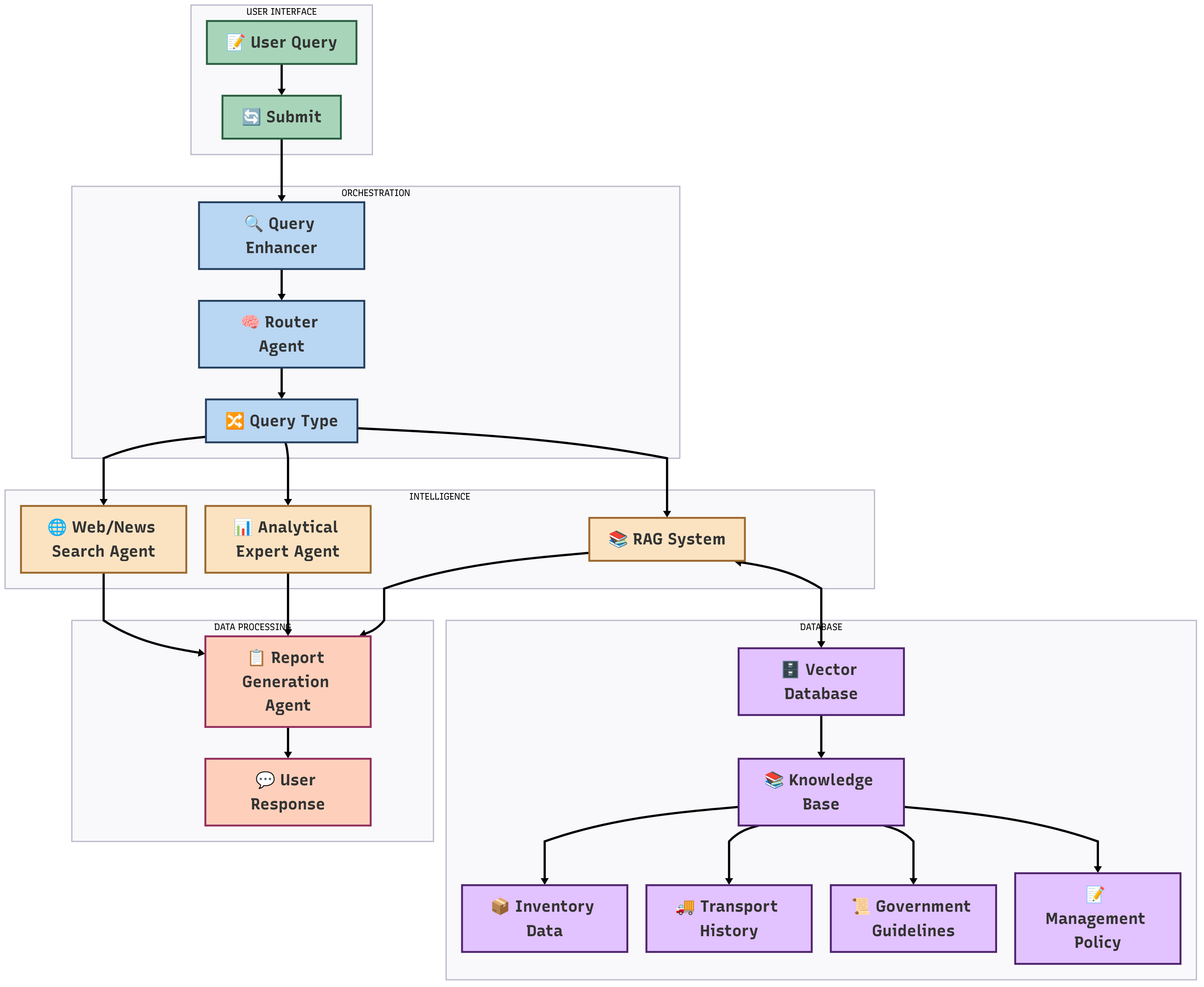

Developed a comprehensive machine learning platform that combines multiple forecasting algorithms including ARIMA time series

modeling, XGBoost regression, and Prophet forecasting with ensemble weighting based on historical accuracy.

Key Responsibilities

| Responsibility Area |

Description & Impact |

|

ML Pipeline Development

|

Engineered ensemble machine learning pipeline combining ARIMA, XGBoost, and Prophet algorithms achieving 9.2% MAPE accuracy

|

|

Feature Engineering

|

Designed comprehensive feature engineering framework incorporating seasonal patterns, promotions, and market factors for enhanced predictions

|

|

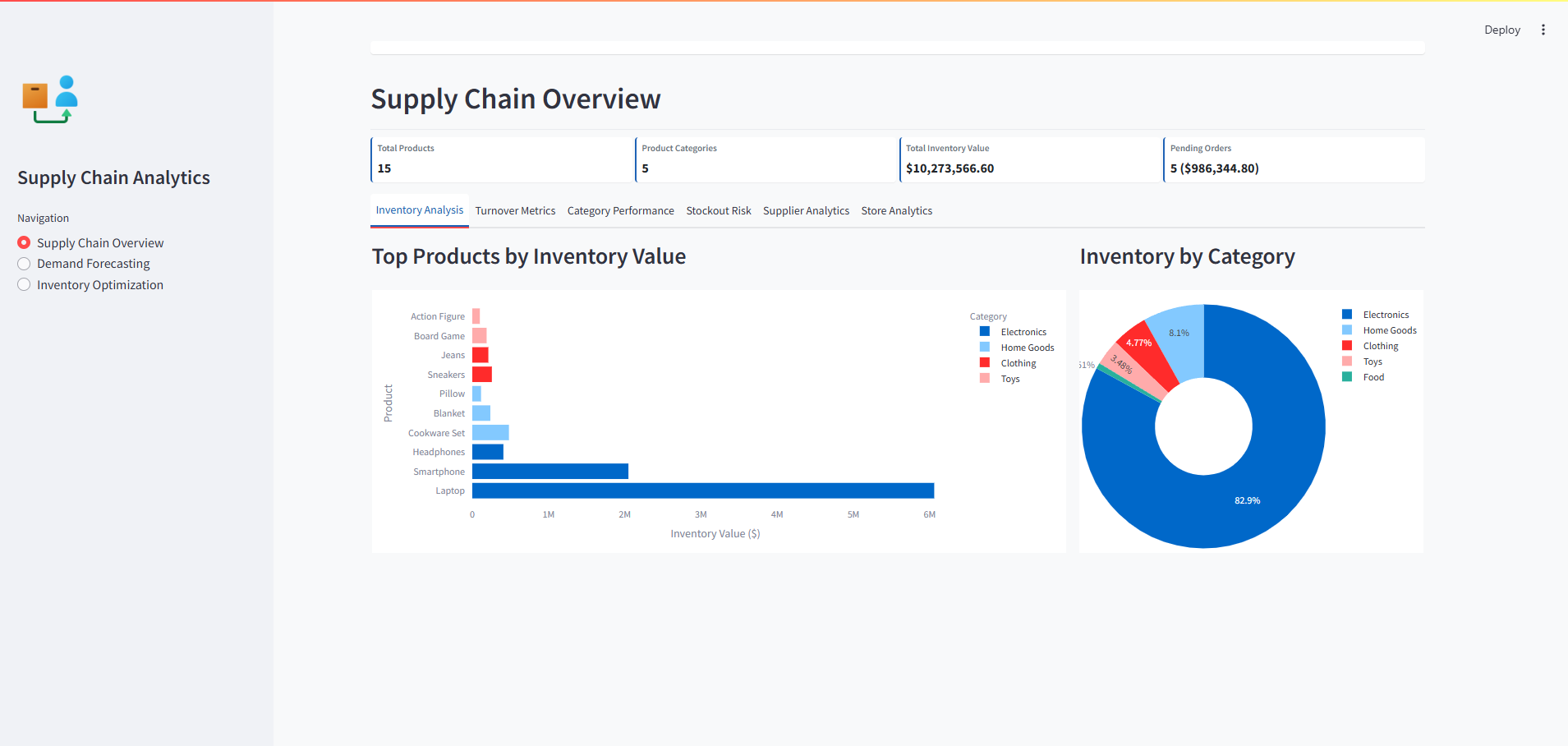

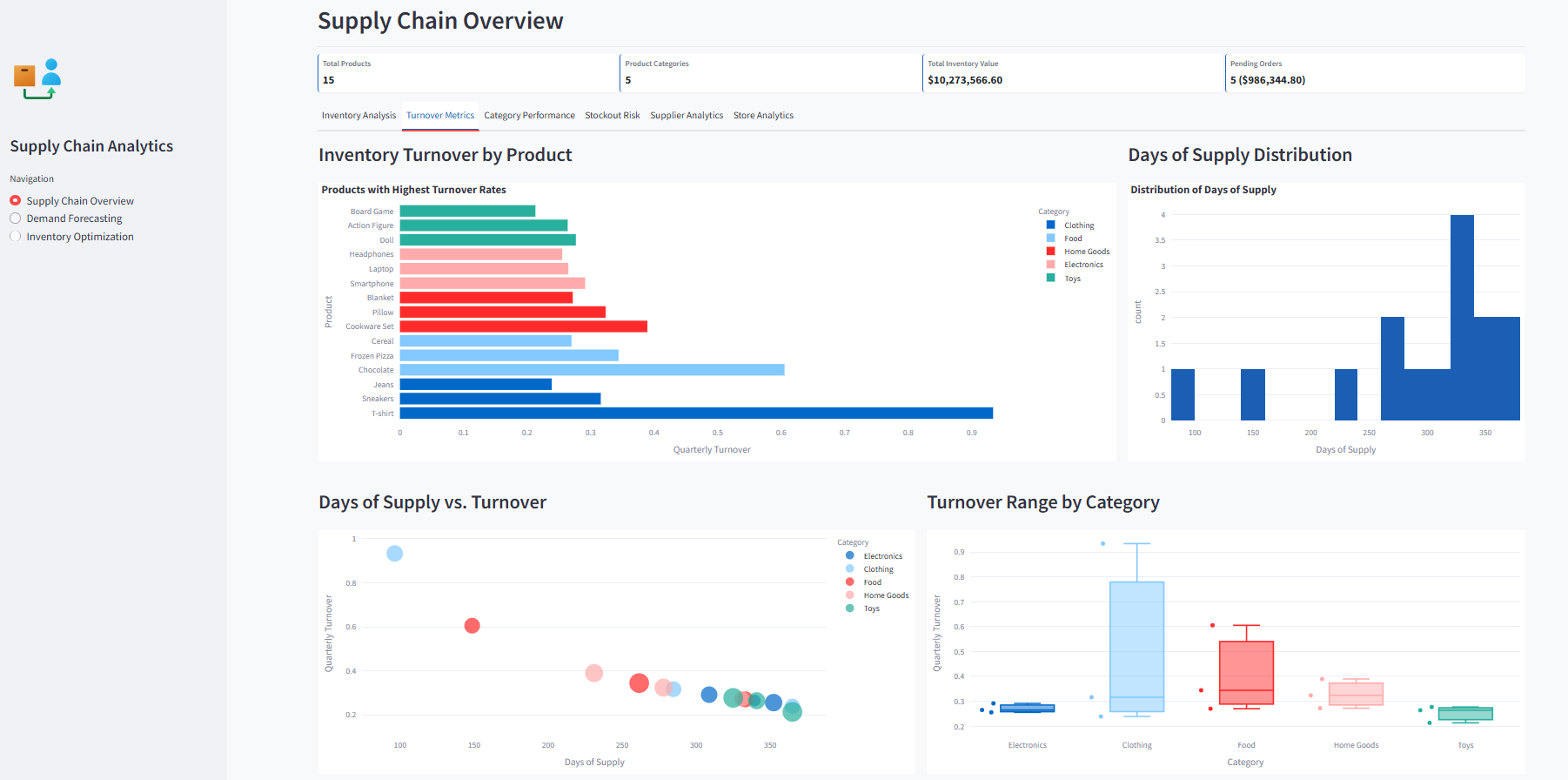

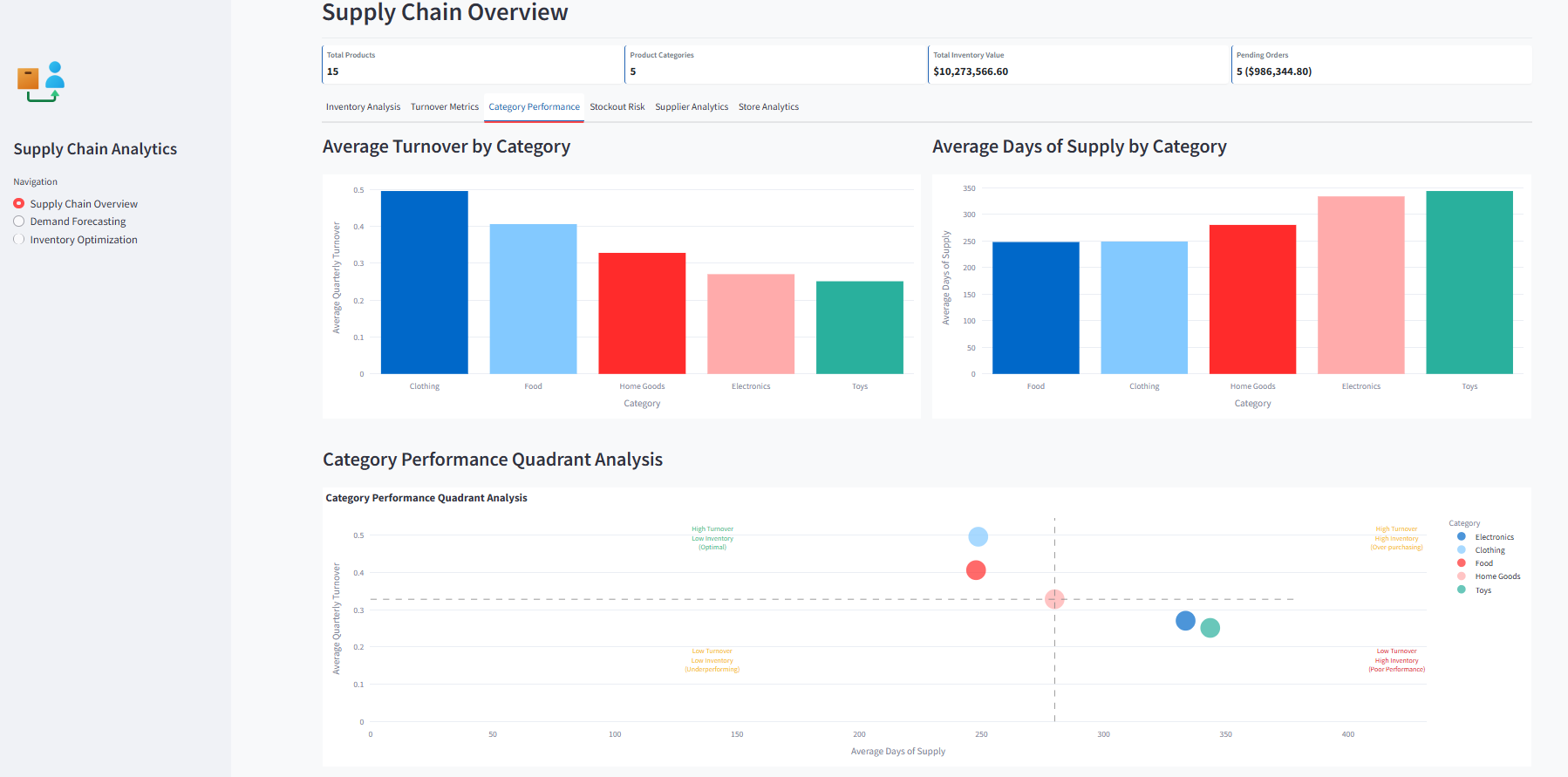

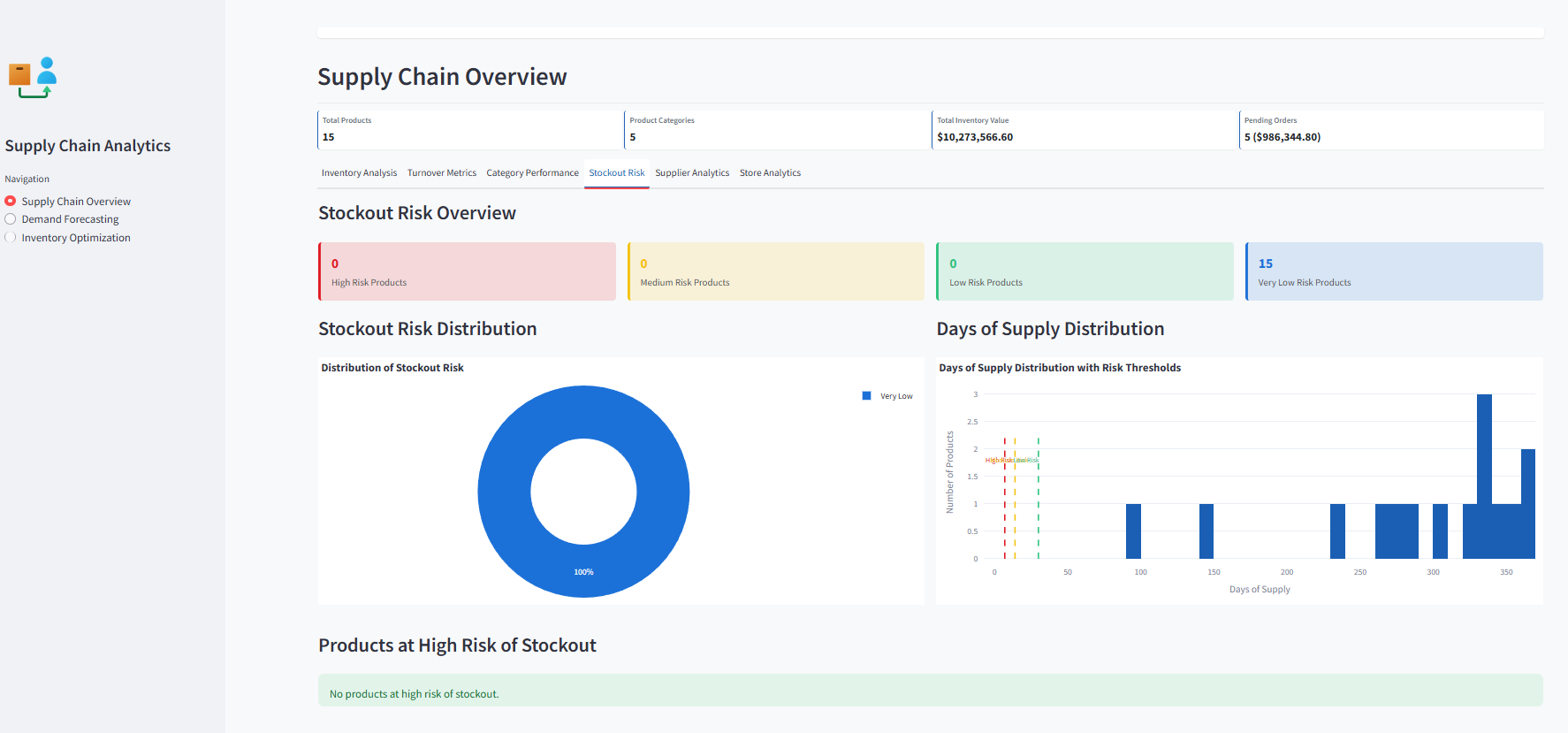

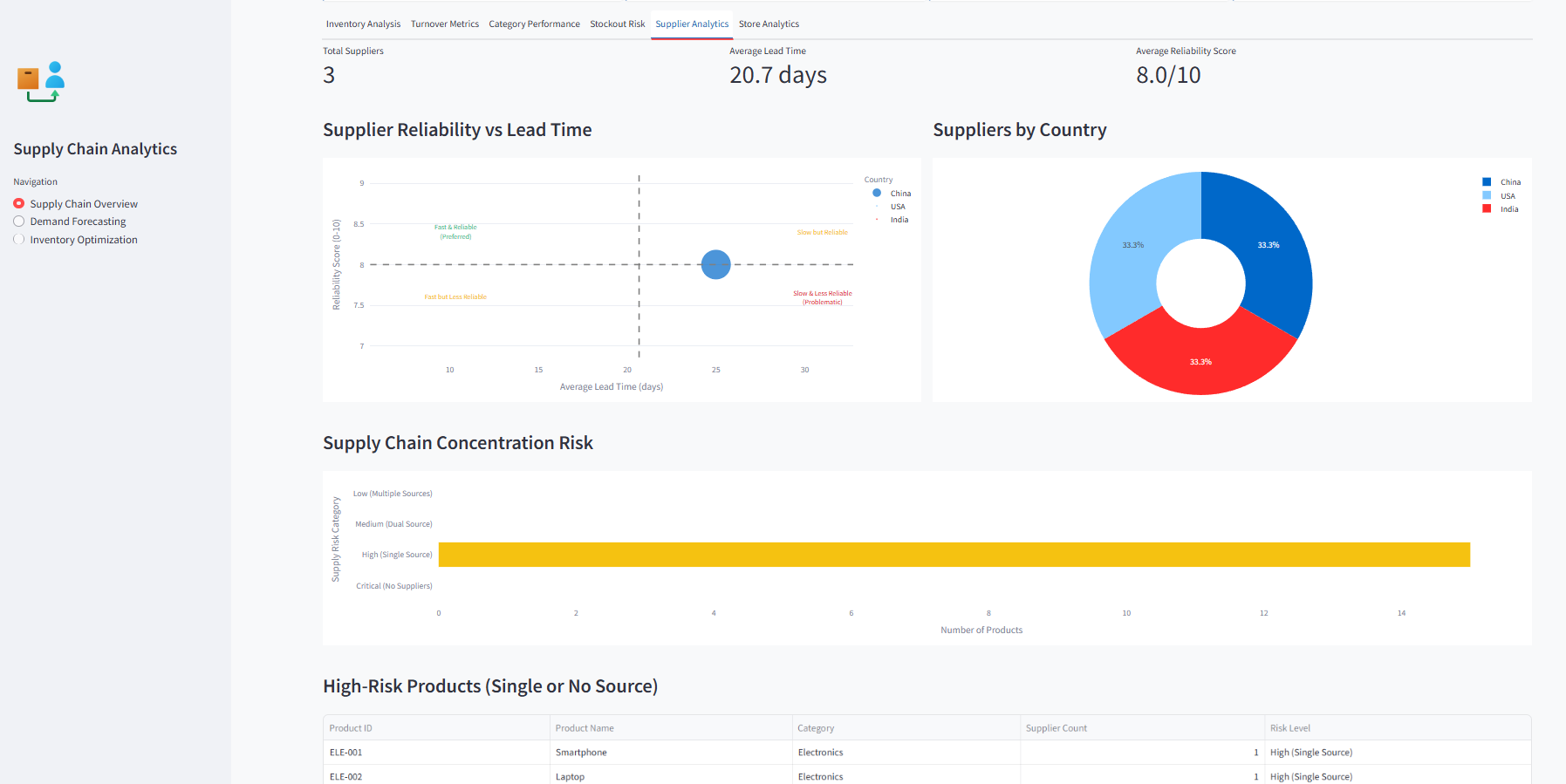

Dashboard Development

|

Built interactive Streamlit dashboard with real-time KPI monitoring, scenario planning, and automated exception reporting capabilities

|

|

System Integration

|

Implemented seamless ERP integration with automated model retraining and continuous improvement mechanisms

|

|

Optimization Algorithms

|

Developed Economic Order Quantity optimization with dynamic safety stock calculations and carrying cost analysis

|

|

Performance Analysis

|

Conducted comprehensive performance analysis demonstrating $3.2M annual savings and 57% reduction in stockout events

|

Key Achievements

Forecast Accuracy (MAPE)

18.5%

9.2%

+50.3%

Inventory Carrying Costs

Baseline

15% reduction

-15%

Stockout Events

4.2% of SKUs

1.8% of SKUs

-57.1%

Forecast Generation Time

3-5 days

4 hours

-95%

Core Components

- Ensemble Machine Learning: Combined ARIMA, XGBoost, and Prophet with automated weighting

- Feature Engineering: Seasonal patterns, promotions, and market factors integration

- EOQ Optimization: Economic Order Quantity with carrying costs and lead time analysis

- Dynamic Safety Stock: Service level-based calculations with demand uncertainty

- Automated Retraining: Continuous model improvement with new data

- Interactive Dashboard: Real-time KPI monitoring and scenario planning

- Exception Reporting: Automated alerts for inventory anomalies

- ERP Integration: Seamless integration with existing enterprise systems

Business Impact & Results

Financial Impact: The 15% reduction in inventory carrying costs translated to approximately $3.2M

in annual savings for the client, while the 57% reduction in stockout events improved customer satisfaction

and revenue retention.

Operational Efficiency: The 95% reduction in forecast generation time allowed for more frequent

updates and adjustments, enabling the organization to respond rapidly to market changes and demand fluctuations.

Strategic Decision-Making: Enhanced visibility into demand patterns and inventory performance

enabled more informed business decisions and strategic planning across all product categories.

Future Enhancements

- International market expansion planned for the coming year

- Integration with external market data and economic indicators

- Advanced supplier collaboration features for demand sensing

- Real-time pricing optimization based on inventory levels